PRONOTEK integrated double stage system

Would you like to know more?

Please contact us directly(China PRONOTEK):

Download product sheet

Central vacuum station Performance advantage

Technical parameters:

| Model | Unit | PNK VS 100-D20 | PNK VS 100-D40 | PNK VS 200-D63 | PNK VS 200-D100 | PNK VS 600-D200 | PNK VS 600-D300 |

|---|---|---|---|---|---|---|---|

| Pumping speed | m3/h | 20×2 | 40×2 | 63×2 | 100×2 | 200×2 | 300×2 |

| Extreme pressure | mbar | 0.5(15) | 0.1(15) | 0.1(15) | 0.1(15) | 0.1(15) | 0.1(15) |

| Buffet tank | L | 100 | 100 | 200 | 200 | 600 | 600 |

| Motor power | Kw | 0.75×2 | 1.1×2 | 1.5×2 | 3.0×2 | 4.3×2 | 7.5×2 |

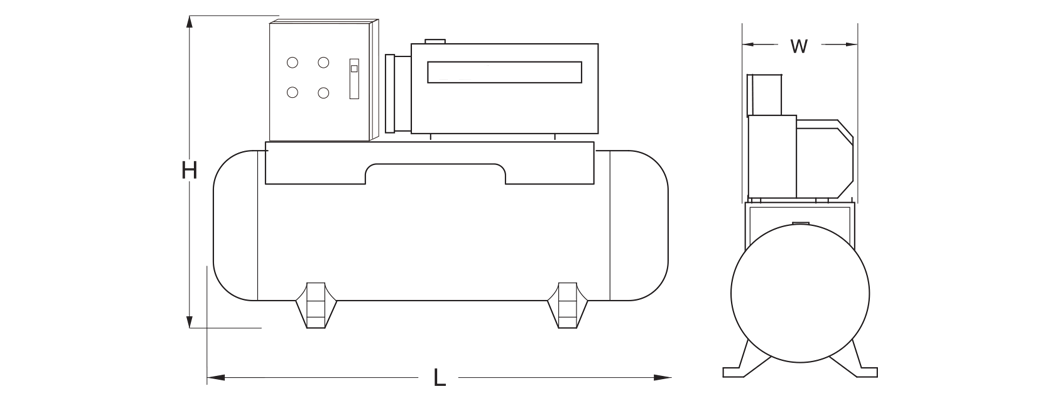

| Dimension(L×W×H) | mm | 1100×425×1000 | 1100×425×1000 | 1300×515×1000 | 1300×515×1000 | 1650×700×1400 | 1650×700×1400 |

| The number and size of vacuum suction inlet | φ12×6 | φ12×6 | φ12×6 | φ12×6 | φ12×6 | φ14×8 |

Installation drawing:

The introduction of vacuum system:

Negative pressure vacuum system consists of central vacuum suction station, suction pipes and negative pressure suction terminals. The negative pressure of the vacuum suction system is vacuumed and pressured by the vacuum pump units in central suction station so as to reach the required negative degree by the vacuum suction pipelines. The negative pressure is used for operation rooms, emergency rooms, and other medical rooms that needs the vacuum suction for medical uses.

The central suction station includes vacuum pump, vacuum tank, negative pressure automatic control cabinet, sewage tank and terminal pipelines. There will be 2 sets of vacuum pumps, one is working and the other is spare, ensuring no shutdown during working. Vacuum tank is a container to store negative pressure and prevent vacuum pump from starting frequently. Negative pressure automatic control cabinet can carry out manual control and automatic control of starting and stop. When the pressure reaches the alarm pressure value, sound alarm and light alarm will be activated, and the lower limit of the alarm pressure is -0.073mpa and the upper limit is -0.019mpa.It automatically put into operation after power failure. Sewage tank is used to store the sewage in the suction pipe system and discharge it regularly. The alarm is installed in the duty room, and its sound can be heard and the light alarm seen within 1.5 meters and its noise level is under 60dBa.

Central negative pressure system(RVM)is making up by one or several rotary-vane vacuum pumps, vacuum storage tank, several filters,PLC electrical control box. With the help of PLC electrical control box, this central negative pressure system can achieve automatic/manual control,failure warning,ensuring the systematic and durable supply in an economic and energy-saving way.

The vacuum system adopts secondary filtration. Generally speaking, the first grade is to filer oil and dust, the second is to filter the bacteria. VC series vacuum pump is the main pump used in this system featuring compact structure, low energy consumption, low noise, stable vacuum, little vibration. Comparing with water ring pump, it is eco-friendly, energy-saving, user-friendly and maintenance friendly. Moreover, it can both use between 0.5mbar (absolute pressure) and 10 mbar (absolute pressure). Meanwhile, the vacuum pump of this specification can be used in closed air or vacuum for a long time, and it can tolerate a small amount of water vapor. But it should prevent from huge amount of water, liquid, corrosive gas and vapor.

Features of vacuum systems:

· high vacuum, reliable performance, long life service

· Air flow:4-1300m3/hr(per pump)

· Vacuum range:0.5-500mbar(absolute pressure)

· No access to water

· Economic Space Occupation with compact design

· user-friendly and maintenance friendly, and low noise

· PLC electrical control box can jointly control several vacuum systems

· Can link to GDMS system

· Comply to CE EN737-3 standard

The system control part of a vacuum system:

· Control the number of opening vacuum pumps according to the amount of air used in the system

· Vacuum indication (with LCD)

· Function indication of procedure, time, maintenance, etc

· alarm indication

· 24-hour monitoring

The accessories of a vacuum system:

· bio-filter

· silencer

· vacuum switch

· vacuum gauge

· remote operation

Specification parameters

Mounting dimensions

Performance curve

Parts

Download

Our vacuum pump products

We are happy to answer any vacuum technical questions you may have

400-966-1558

Contact Us

Service demand

400-966-1558

8:30-17:30 on weekdays

Italian R & D and manufacturing technology

The world's leading manufacturer of vacuum pumps and vacuum systems

PRONOTEK

Building A, North District, Goldman Sachs Science Park, Nancheng District, Dongguan City, Guangdong Province

+86 (0769) 8978 4003

+86 (0769) 2202 6929

sales@pronotek.com

Products and Services

Industry solutions

©2017~2021 PRONOTEK VACUUM All Rights Reserved. 粤ICP备17034033号-1